Customer challenges

- The client wished to perform Simultaneous Operations (SIMOPS) including Coiled Tubing frac and clean-out operations on one well whilst simultaneously drilling another, using a jack-up drilling rig to allow the project to be delivered in a timely and cost-efficient manner

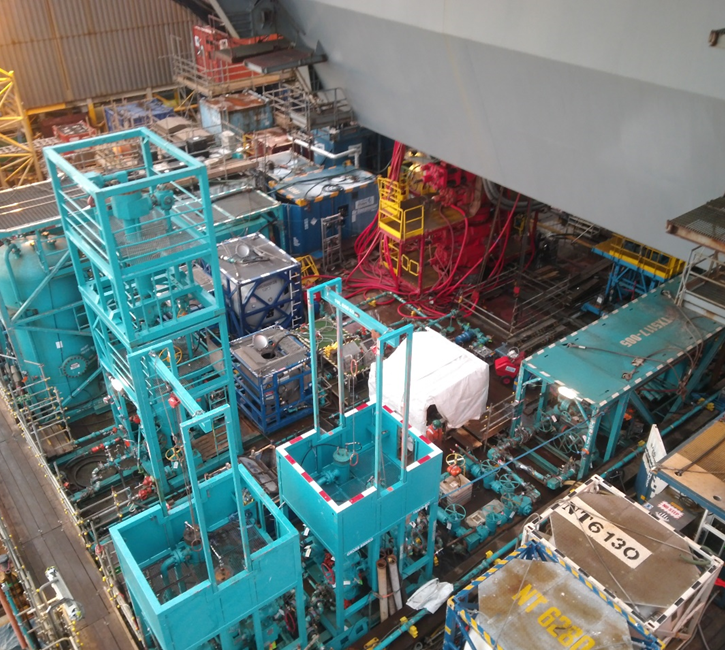

- All equipment for Coiled Tubing and frac flowback operations was to be located on the platform deck, where space was limited

- All produced fluids were to be processed direct to production or re-injected, allowing for zero discharge to environment

- All solids needed to be removed from the produced fluids prior to sending to production facilities

- The solids-exclusion package was to be integrated with platform safety systems

- High liquid and solids return rates were anticipated, along with the potential for hydrates - presenting challenging operating conditions

- Performance was required to be monitored in realtime, with data transmission to the Operator’s offices, onshore

Expro Excellence

- Expro designed a small-footprint, bespoke, continuous solids-management system which was fully integrated into the platform’s safety systems and limited available deck space; achieving complete solids removal from the frac flowback fluids before sending onward to production

- Concurrent monitoring of multiple wells was achieved through EDGE Data to Desk; an enhancement to the originally-requested scope of work

- Liquids were successfully reinjected back into the production train using high-rate, high-pressure injection pumps

- Expro’s solids-management system was refined to operate as a ‘hands-free’ process with electronic solids measurement and vacuum pump solids removal system to limit operator exposure

- 100% Job Performance Reports scores, with specific reference made to the professionalism and teamwork of the Well Test crew

Value to client

- Zero HSE events or service quality issues

- Two successfully drilled and fracked wells with zero NPT incurred

- 100% uptime achieved – with no interruption to operations required to handle process returns

- New wells extended the lifetime of the platform

- Time and cost-savings through SIMOPS

- EDGE Data to Desk enhanced operational efficiency