Customer challenges

- A new multi-lateral oil and gas well in East Texas was producing over 1,000 barrels of water a day

- The client sought a solution to isolate the water source downhole, which in turn would optimise production and reduce expensive water disposal costs

Expro Excellence

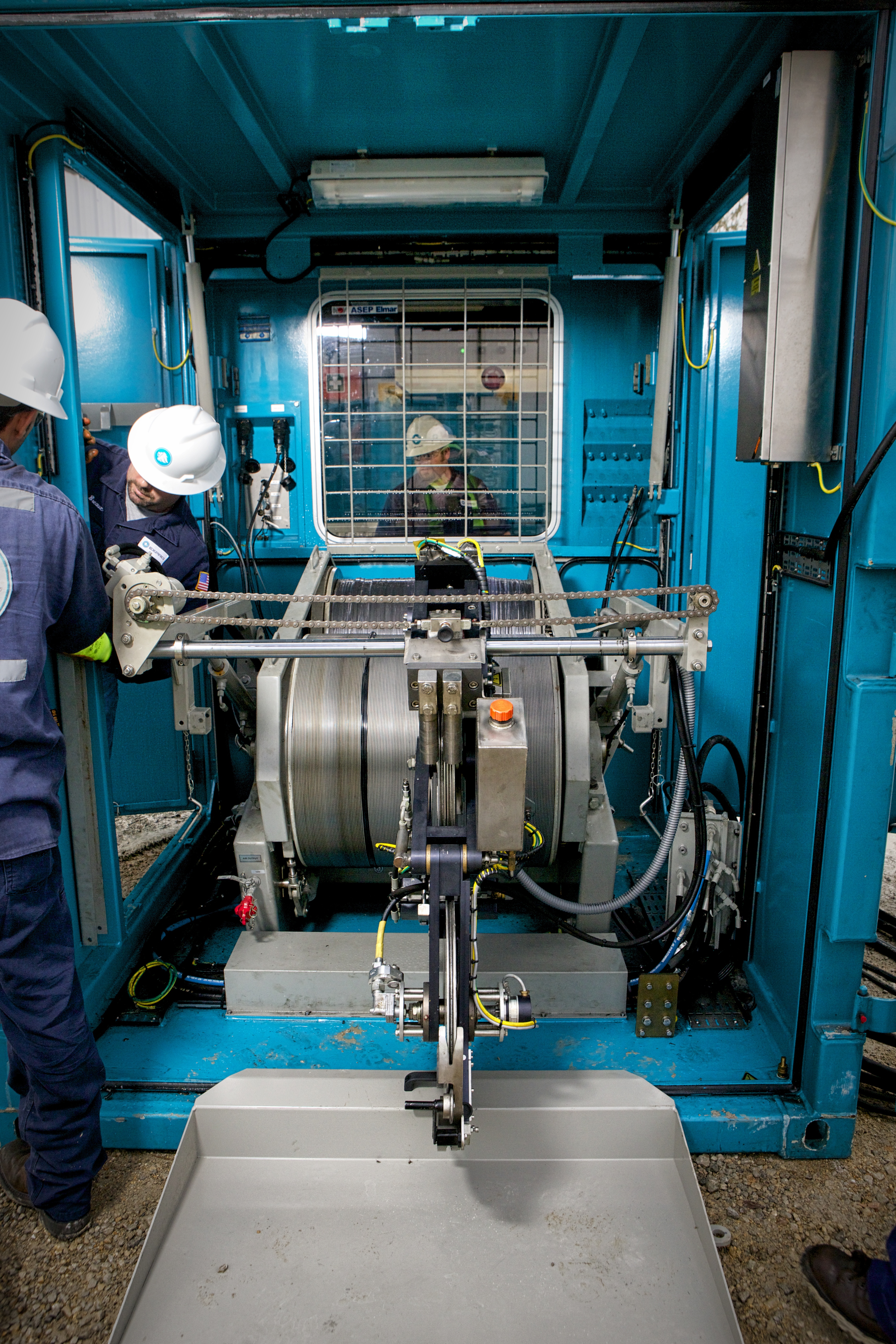

- Expro proposed a custom production logging tool string to ascertain which lateral section was the source of the water - the well was flowing at 40% water cut (mainly from one lateral), when only 5-10% was expected

- Produced in-house, it was critical that the custom production logging tool string's sensors were capable of passing through small restrictions in the tubing, while simultaneously running a fluid density inertia (FDI) tool to help water/oil phase identification - the tool string was able to pass through a 2 3/8" x-nipple with an internal diameter of 1.865"

- Combined with the FDI tool, the pressure and temperature sensors allowed Expro to characterise each phase type within the well, and their point of entry to the wellbore

- The main wellbore plus one additional lateral were successfully logged; the well was entered twice, over two days

- The liner top was 9,500 ft (vertical); the wells went horizontal after entering the lateral sections; running e-line in surface read out (SRO) Expro were able to enter the lateral sections to about 70 degrees deviation - this was sufficient to ascertain if there was water production in each lateral

- Expro log interpretation specialists provided appropriate onsite analysis for where water shut off should happen

Value to client

- Tailored solution: modifications and collaboration with the client to find the solution followed by some temporary patch and packer options to isolate the water producing zones

- Enhanced data: wealth of data collated allowed the client to identify the water source and plan for future remediation; real-time SRO facilitated faster decision making

- Efficiency: running the custom logging string (with multiple sensors) in tandem with the FDI on one string saved two full days crew time as well as avoiding the use of a rig as an e-line unit and picker were used instead

- Final water cut reduced to between 5-10%