Customer challenges

- A customer with existing operations in Egypt's Eastern desert approached Expro about an innovative approach to improve production from their heavy oil (10-12 API) reservoir

- Performance from this heavy oil field had been well documented and presented some difficult challenges, with reservoir depths being very shallow, low BHT, low BHP, and naturally fractured dolomite with a history of water production. Steam injection had previously been tried, however this had only been marginally successful

- Many types of completion techniques had also been tried, from standard perforating to propellants, however none has proved optimum as production rapidly decrease after steam injection

Expro Excellence

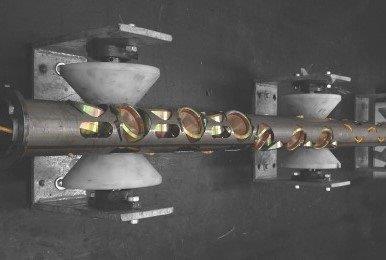

- Existing technology was not an effective solution, so Expro through close collaboration with Delphian Ballistics ( a third party supplier), provided an innovative and cost-effective solution called TriStim®. TrimStim® uses a standard perforating charge but also angles them within the special gun system - this allows the perforations to converge making a single layer tunnel with less crush zone or debris

- Modelling was performed by both Expro's EGIS team and Delphian's reservoir engineer - both found the reservoir to be a good candidate for the proposed technology

- Expro modified the Bottom Hole Assembly (BHA), using special equipment and techniques in order to complete the job. The team had to overcome low BHP which restricts most TCP firing heads and accessories which depend on applied pressure for activation

- Expro were able to develop a customised fast-track technical solution based on modelling results from the customer's reservoir

Value to client

- The selected well was previously producing but production had ceased. It was selected to compare production results before and after using the TriStim® technology

- Immediately after perforation, oil production jumped from zero to - 5 bopd and this was maintained for 30 days

- Expro's local infrastructure and resources

- Customer was extremely happy with the results and they plan to use the technology in the future to rejuvenate their well stock and deliver incremental production